Search by posts

Calendar

Categories

Popular posts

News

By Admin

By Admin

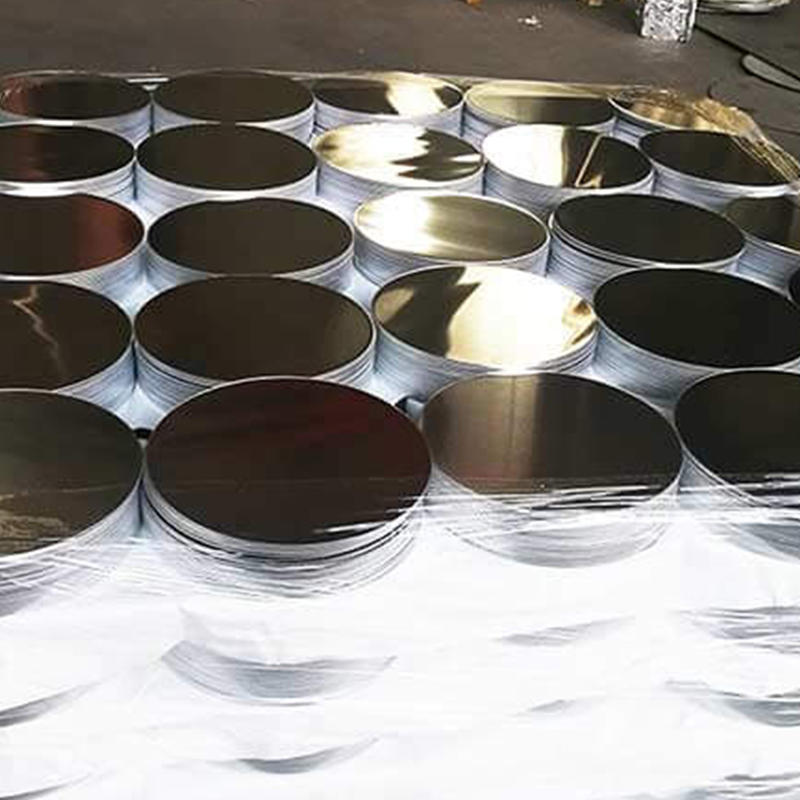

Why does aluminum round have better forgeability?

The fundamental reason why aluminum circles have good forgeability lies in their crystal structure and metallic properties. The face-centered cubic (FCC) crystal structure of aluminum gives it a larger space in the crystal lattice, making it more susceptible to deformation and less likely to break when subjected to external forces. In addition, aluminum has a relatively low melting point and high plasticity, making it plastic over a wide temperature range. This low melting point also helps improve forgeability, allowing aluminum to become liquid at lower temperatures.

During the processing process, the crystal particles of aluminum slide relatively easily against each other through grain boundary slip, prompting deformation to proceed and helping to achieve forgeability. Through appropriate heat treatment and deformation treatment, aluminum can form a fine and uniform grain structure. This microstructure improves the material's forgeability.

Combining these factors, aluminum is an ideal choice for manufacturing a variety of components and products, and is widely used in construction, aerospace, automobile manufacturing and other fields. The superior forgeability of aluminum circles not only comes from the characteristics of the material itself, but is also affected by appropriate processing methods and process control.