Product category

Product category

About Zhongbang

Ningbo Zhongbang Aluminium Co., Ltd. is professional China Aluminum Sheet Manufacturers and wholesale Aluminum Sheet factory.It committed to providing you with reliable quality and service. We specialize in aluminium processing and manufacturing, specializing in various brands of aluminium circles, aluminium ovals, aluminium sheets, aluminium strips and aluminium coils, serving a wide range of aluminium applications, including kitchenware, new energy vehicle battery cases, industrial, building materials and so on. Our Chinese factory is located in Cixi, Ningbo, 30 kilometres from Ningbo port, with extremely convenient trade and shipping conditions.

Zhongbang has obtained ISO9001:2015 and TS16949 certifications, and has a good performance in independent innovation. Through unremitting efforts, Zhongbang has become more and more outstanding, daring to break through the established standards in the industry and face the competition head-on.

Zhongbang has always focused on the needs of our customers, and we have strict quality control standards and testing methods to achieve our commitment to quality. Zhongbang Aluminium, the representative of quality and efficiency.

Honor

-

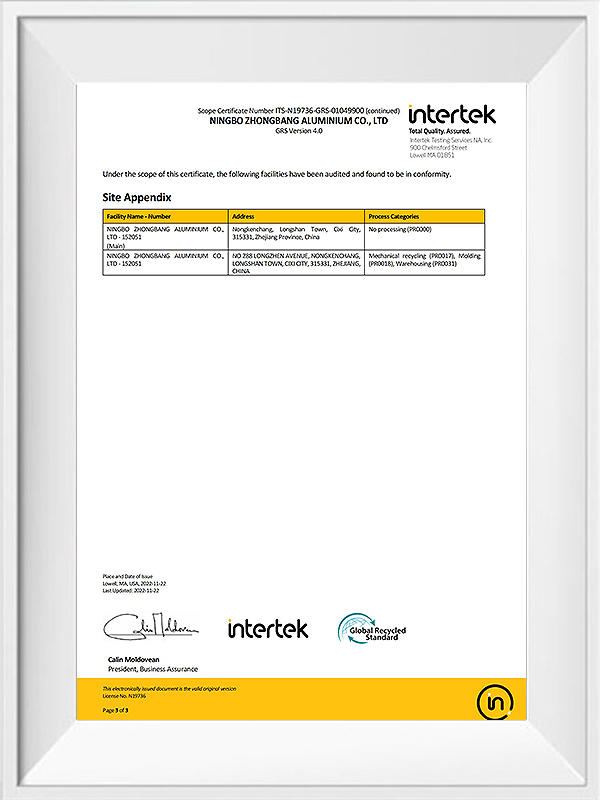

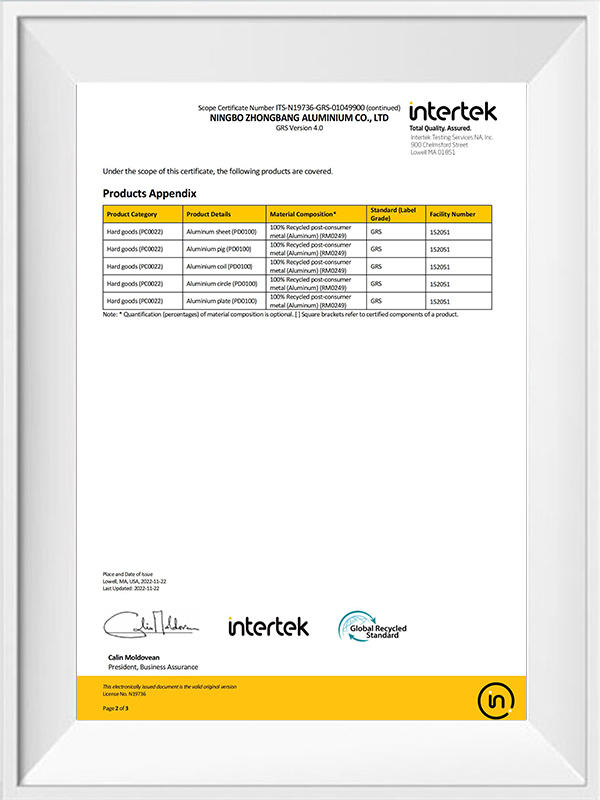

SC-GRS-Certificate

SC-GRS-Certificate -

SC-GRS-Certificate

SC-GRS-Certificate -

SC-GRS-Certificate

SC-GRS-Certificate -

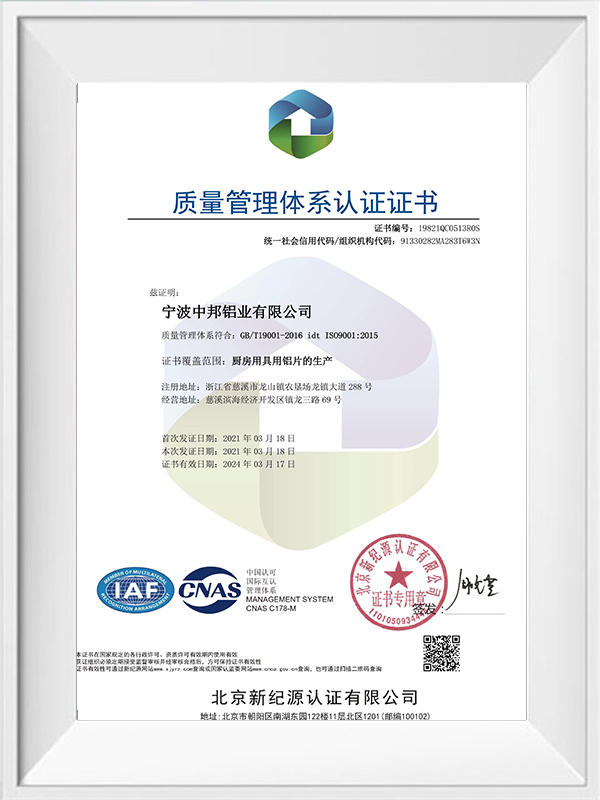

Quality Management System Certification Certificate

Quality Management System Certification Certificate

LATEST NEWS

-

How do manufacturers customize the production of Aluminum Coil?

2024-07-26

2024-07-26

In the production field of Aluminum Coil, there are often significant differences in the performance requirements of products across different industries. In order to meet these diverse needs, as a professional manufacturer, we have adopted a flexible product customization production strategy. We engage in in-depth communication and exchange with our clients to fully understand their specific application scenarios, performance requirements, and cost budgets. Based on this information, our R&D team will conduct a detailed requirements analysis to determine key parameters such as alloy composition, thickness, width, and surface treatment of the product. For example, in the aerospace industry, products need to have characteristics such as high strength, corrosion resistance, and lightweight; In the field of architecture, more emphasis is placed on the aesthetics, processability, and cost-effectiveness of products. After determining the product parameters, our production team will adjust the production process and workflow according to customized requirements. For example, by adjusting the proportion of alloy elements added and the heat treatment process, the mechanical properties and corrosion resistance of the product can be changed; By optimizing the rolling process and surface treatment technology, the flatness and surface quality of the product can be improved. In the production process, we will also adopt advanced online monitoring systems and strict quality control measures to ensure the stability and consistency of product performance. In addition to adjusting production processes, we also focus on close cooperation with upstream and downstream enterprises in the supply chain. By establishing long-term and stable cooperative relationships with raw material suppliers, equipment manufacturers, and testing institutions, we can ensure high-quality supply of raw materials, stable operation of production equipment, and reliable guarantee of product quality. This close supply chain cooperation mechanism provides strong support for customized production of products.

Read More -

How to ensure the dimensional accuracy and flatness of the product in the production process of Aluminum Coil?

2024-07-19

2024-07-19

As a professional manufacturer of Aluminum Coil, we are well aware that in high-end applications such as aerospace, precision electronics, etc., there are extremely high requirements for the dimensional accuracy and flatness of our products. To ensure that our products meet these strict requirements, we have adopted a series of refined production processes and strict quality control measures.In terms of raw material selection, we carefully select high-quality aluminum ingots as production materials to ensure the purity and consistency of the raw materials. Subsequently, during the hot or cold rolling process, we use advanced rolling equipment and precise control systems to precisely control key parameters such as rolling force, rolling speed, and temperature. The precise control of these parameters is crucial for ensuring the dimensional accuracy of the product. At the same time, we also regularly grind and maintain the rollers to ensure their surface flatness and dimensional accuracy, thereby further improving the flatness of the products.After rolling is completed, the product will undergo strict dimensional inspection and flatness verification. We use high-precision measuring instruments and equipment to accurately measure the thickness, width, length, and other dimensions of our products, ensuring that they meet the established specifications. For flatness, we conduct visual inspection, touch inspection, and use professional flatness testing instruments to ensure that the surface of the product is flat and free of defects such as ripples, protrusions, or depressions.In addition, in order to further improve product quality, we have also introduced an online monitoring system to provide real-time monitoring and data collection for various stages of the production process. Through these data, we can promptly detect abnormal situations in the production process and take corresponding adjustment measures to ensure that the dimensional accuracy and flatness of the product are always maintained at a high level.

Read More -

How to ensure the strength and stability of Aluminum Sheet during welding and connection?

2024-07-12

2024-07-12

Ensuring the strength and stability of Aluminum Sheet during welding and connection requires selecting the appropriate welding process. For example, TIG welding is suitable for thin Aluminum Sheet, providing high precision and less heat-affected zone, while MIG welding is suitable for thicker Aluminum Sheet, with high welding speed and good filling ability. Although laser welding has high precision, it is more expensive. Before welding, the surface of Aluminum Sheet must be prepared to remove the naturally formed aluminum oxide film, which can be achieved by chemical cleaners or mechanical grinding. Ensure that the surface of Aluminum Sheet is clean and free of oil or dirt. Selecting welding filler materials compatible with Aluminum Sheet materials and high-purity shielding gases (such as argon or helium) is also key to ensuring welding strength. Controlling welding parameters is equally important. According to the thickness of Aluminum Sheet and the selected welding process, adjust the appropriate current, voltage and welding speed to ensure appropriate heat input and penetration depth to avoid overheating or too fast cooling. Accurately positioning and clamping the Aluminum Sheet before welding to avoid movement or deformation during welding can improve the stability and strength of the welded joint. Post-weld treatment includes removing weld defects such as pores, slag inclusions or cracks, which may require grinding or repair. In addition, for applications that require further strength improvement, heat treatment (such as annealing or aging) can be performed to improve the performance of the welded area. Non-destructive testing (such as ultrasonic testing, X-ray testing) and mechanical testing (such as tensile, shear or bending tests) are performed on welded joints to evaluate their internal defects and mechanical properties to ensure that they meet the design requirements.

Read More -

How safe is the Aluminium Circle 1000 series for use in the food processing industry?

2024-07-05

2024-07-05

In the food processing industry, Aluminum Circle 1000 series is widely used in various food contact equipment and containers due to its excellent safety and applicability. This aluminum alloy is usually pure aluminum or an alloy close to pure aluminum, so its non-toxicity and corrosion resistance are one of its main advantages. Pure aluminum does not contain harmful substances and is not prone to chemical reactions with ingredients in food, thus ensuring the purity and safety of food. Its surface is smooth and not easy to rust, which is conducive to maintaining the hygiene of food contact surfaces, which is crucial for hygienic requirements during food processing. The processing performance of Aluminum Circle 1000 series is also one of the important reasons for its selection. This aluminum alloy is easy to process and clean, helping to create easy-to-clean food processing equipment and containers, which can effectively reduce the risk of food contamination and cross-contamination. Its material structure allows it to withstand various stresses and temperature changes during food processing, maintaining stability and durability, and is especially suitable for use under long-term or high-temperature conditions. In addition, the Aluminum Circle 1000 series also offers significant advantages in terms of environmental friendliness. As a recyclable material, aluminum is easy to recycle and reuse, helping to reduce resource consumption and environmental impact. Through reasonable resource utilization and recycling, the negative impact on the environment can be further reduced, in line with the concept and practice of sustainable development. Manufacturers and processors typically follow strict food safety and hygiene standards when selecting and applying Aluminum Circle 1000 series. Ensure that materials comply with relevant regulatory requirements and that necessary hygiene measures are taken during the manufacturing process to ensure that the food contact equipment and containers produced do not pose any potential risks to food quality and consumer health.

Read More -

What is the thermal conductivity and conductivity of aluminum plates?

2024-06-28

2024-06-28

Aluminum Sheet, This lightweight metal material, with its excellent thermal and electrical conductivity, occupies a pivotal position in the modern industrial field. Its thermal conductivity is almost comparable to that of silver and gold, making aluminum plates a leader in heat dissipation solutions. In electronic devices, especially in high-performance computers, communication devices, and electric vehicles, thermal management is a crucial challenge. The efficient heat dissipation performance of aluminum plates makes them an ideal choice for manufacturing key components such as heat sinks and battery casings, effectively ensuring the stable operation of these devices. In addition to excellent thermal conductivity, the conductivity of Aluminum Sheet is also extremely excellent. Although its conductivity is slightly inferior to silver and gold, aluminum plates are widely used in the power industry due to their high cost-effectiveness. Aluminum plates play a crucial role in critical components such as transmission equipment such as cables and busbars, as well as internal windings of transformers. Its excellent conductivity ensures the stable transmission of electrical energy, while its lightweight and corrosion resistance also improve the overall performance and service life of the equipment. In the transportation industry, aluminum sheets are also widely used. Its lightweight characteristics reduce the overall weight of transportation vehicles, improve fuel efficiency, and its high strength and excellent thermal conductivity ensure the safety and comfort of the vehicle. Whether it's cars, trains, or airplanes, aluminum plates play an irreplaceable role.

Read More -

How does Aluminium Circle 1000 series perform in cold bending and deep drawing?

2024-06-21

2024-06-21

Aluminium Circle 1000 series exhibits specific advantages in cold bending and deep drawing. Made from high-purity aluminum, these aluminum circles have good cold bending properties and can be processed into the required curved shapes at room temperature through appropriate processes. This excellent cold bending performance makes them an ideal choice when curved components or products with specific shapes need to be manufactured. However, compared with some other aluminum alloys, Aluminum Circle 1000 series may be more limited in deep drawing performance. Due to the characteristics of pure aluminum materials, its hardness and strength are relatively low, which requires more careful and precise processing control when deep drawing to avoid irreparable deformation or premature cracking of the material. Nevertheless, Aluminium Circle 1000 series performs well in general cold forming processes, such as calendaring and some stamping operations. These processes are generally used to produce parts and components that require simple shapes and good surface quality. The advantages of its high-purity aluminum materials are also reflected in its good processing properties, which means that they can be cut, welded and other mechanical processing operations relatively easily to meet the needs of various applications. However, in situations where higher strength and more complex shapes are required, especially in applications that require deep stamping, the application of Aluminum Circle 1000 series may be limited. In order to meet these special requirements, it is usually necessary to consider the selection of more suitable aluminum alloys or special aluminum materials with enhanced characteristics. This choice can not only ensure the stability and reliability of the product during processing, but also improve the performance and durability of the final product. Therefore, when selecting Aluminum Circle 1000 series and applying it to a specific project, it is necessary to fully consider the physical properties of the material, the processing requirements, and the design and use environment of the final product. By comprehensively considering these factors, it can be ensured that the most suitable material is selected, so as to ensure that the product can achieve the best performance and quality standards during manufacturing and use.

Read More -

How does 1050 aluminum disc perform at high temperatures? Is it suitable for high temperature applications?

2024-06-14

2024-06-14

The performance characteristics of 1050 Aluminum Circle at high temperatures are mainly affected by the characteristics of its aluminum alloy itself. Aluminum alloy has good thermal stability and certain corrosion resistance. The melting point of aluminum alloy is about 660°C (1220°F), and it still maintains certain thermal stability at high temperatures. However, the strength and hardness of 1050 Aluminum Circle will decrease significantly with increasing temperature. In addition, aluminum is easily oxidized in high temperature environments to form an oxide layer. Although it can provide certain corrosion protection, it may still undergo rapid oxidation and corrosion under some extreme high temperature and oxidizing conditions. Therefore, 1050 Aluminum Circle is suitable for high temperature applications in the low to medium temperature range, such as applications in the range of 100°C to 200°C. This includes applications such as components of some light industrial equipment, heat exchangers and heat sinks. In addition, it can also be used as an auxiliary component of thermal insulation materials or in high temperature environments that require high thermal conductivity and certain corrosion resistance. 1050 Aluminum Circle is not suitable for high temperature environments exceeding 200°C, nor for long-term use under high load and high stress conditions, as its strength and stability may not meet these requirements. Therefore, when selecting 1050 Aluminum Circle for high temperature applications, it needs to be evaluated and selected based on the specific temperature conditions, mechanical requirements and corrosion resistance to ensure that it can provide reliable performance and service life in the expected environment.

Read More -

Is there a correlation between the strength of an aluminum coil and its grain size?

2024-06-07

2024-06-07

As a common metal coil, aluminum coil has a wide range of applications in engineering and manufacturing. Its mechanical properties, especially strength, are crucial for its application in different fields. Among the mechanical properties of aluminum coil, grain size plays a key role. Grain refinement has a significant effect on the strength of aluminum materials. Generally, aluminum coils with smaller grains have higher strength. This is because aluminum materials with smaller grains have more grain boundaries, which effectively restrict the movement of dislocations. When the material is subjected to external forces, grain boundaries can effectively prevent the propagation of dislocations, thereby increasing the material's resistance to deformation. In addition, aluminum coils with smaller grains are also more prone to grain boundary sliding and grain boundary bending during deformation, which increases the deformation resistance of the material and improves its strength. Grain size is also closely related to the fracture toughness of aluminum coils. Although grain refinement can improve the strength of aluminum materials, it may reduce its fracture toughness in some cases. This is because grain refinement increases the number of grain boundaries, which are weak areas in the material and easily become the starting point of cracks, thereby reducing fracture toughness. Therefore, in the design and manufacturing process of aluminum coils, it is necessary to balance the relationship between strength and toughness, and to obtain aluminum materials with both good strength and good toughness by controlling the grain size and grain morphology. In the production process of aluminum coils, heat treatment is a common method to adjust the grain size. By controlling parameters such as heating temperature, holding time and cooling rate, grain growth or refinement can be achieved. In addition, the addition of alloying elements and composition adjustment can also affect the size and morphology of grains. For example, adding a certain amount of micro-alloying elements, such as vanadium and manganese, can effectively refine the grains and improve the strength of aluminum coils.

Read More -

How to surface treat aluminum sheet to increase its corrosion resistance?

2024-05-31

2024-05-31

As a material widely used in various industrial and commercial fields, the corrosion resistance of aluminum sheet is crucial to its service life and performance. In order to enhance the corrosion resistance of aluminum sheet, a variety of surface treatment methods are usually used. One of the common surface treatment methods is anodizing. Anodizing improves the surface hardness and corrosion resistance by forming an oxide layer with a thickness of about 5-25 microns on the surface of aluminum. This oxide layer not only improves the weather resistance of aluminum sheet, but also can be dyed or sealed as needed to enhance its decorative and functional properties. This treatment method is widely used in aerospace, automotive, construction and other industries, providing a cost-effective protection and decoration technology. Although aluminum itself is not easy to electroplate, it can be electroplated with nickel, chromium, zinc or other metals after chemical treatment to increase its surface corrosion resistance and decorative properties. The electroplating layer not only provides an additional protective layer, but also improves the appearance and hardness of the aluminum sheet, which is widely used in automotive parts, household appliances and other fields. In addition, coating technology is also an effective surface treatment method that can form an organic or inorganic coating on the surface of aluminum sheet. Polyester coating (PE) and fluorocarbon coating (PVDF) are two common types of coatings that can not only improve the corrosion resistance of aluminum panels, but also improve their weather resistance and appearance. This method is commonly used in applications such as building exterior wall panels, billboards and home decorations that require long-term color and surface maintenance.

Read More -

What is the molding performance of 1050 Aluminum Coil?

2024-05-24

2024-05-24

1050 aluminum coil is widely used in industrial processing fields due to its good forming properties. It has excellent bending performance and can be easily bent into various shapes at room temperature, such as bent pipes or bent plates. This softness and formability make 1050 aluminum coil ideal for use in the manufacturing industry as it is capable of adapting to a variety of complex processing needs, from simple bends to complex curved shapes. At the same time, 1050 aluminum coils also perform well in stretching and can change their shape and size through stretching processing. This tensile property allows it to be used in production to manufacture various parts and components, such as stretch forming and stretch stamping under stretch forming processes. 1050 aluminum coil usually has excellent deep drawing performance, which means that it can be used in deep drawing forming processes, such as stamping, punching, mold forming, etc., to manufacture more complex parts and components. This property makes 1050 aluminum coil one of the materials of choice in automotive, aerospace and other fields, as these fields often require complex shapes and designs. During processing, 1050 aluminum coils may experience some degree of hardening, especially during cold working. Therefore, careful consideration is needed when selecting processing processes and conditions to ensure that no cracks or deformations occur during hardening. This requires an in-depth understanding of the physical properties and processing parameters of the material and taking appropriate measures to optimize the processing to ensure the quality and performance of the final product.

Read More -

What are the processing techniques for aluminum coils?

2024-05-17

2024-05-17

Aluminum coil is an important metal material that plays an important role in various industries. In order to meet the needs of different industries, aluminum coils use a variety of processes during processing. These processes can be applied individually or in combination to change the shape, thickness, surface properties and functions of the aluminum coils. Cutting is one of the basic processes in aluminum coil processing. The aluminum coils are cut according to the required size and shape through shearing, cutting machine or laser cutting to meet the size requirements of different products. The precision and efficiency of the cutting process are crucial for subsequent processing steps. Stretching is another common processing process that uses a stretching machine to stretch aluminum coils into products of different shapes and sizes. This process is often used in the production of products such as wire drawing and tube drawing, and can meet high requirements for product strength and shape. The bending process can change the shape and angle of the aluminum coil. Using a bending machine, aluminum coils can be bent into required shapes, such as angle irons, profiles, etc., for use in construction, machinery manufacturing and other fields. Rolling is a process in which aluminum coils are rolled through a rolling mill to change their thickness and width. This process is commonly used to produce aluminum plates and foils of various specifications and thicknesses, and is suitable for construction, electronics, packaging and other fields. The welding process is used to join aluminum coils into a whole, or to repair surface damage to aluminum products. Common welding methods include argon arc welding, laser welding, etc., which can ensure the firmness and sealing of the welded part. In addition, surface treatment processes such as polishing, anodizing, electroplating, and spraying are also important links in aluminum coil processing. Through these processes, the surface finish, corrosion resistance and decoration of aluminum coils can be improved to meet the surface quality requirements of different industries.

Read More -

What are the characteristics of 3105 Aluminum Circle compared with other aluminum alloy discs?

2024-05-10

2024-05-10

3105 Aluminum Circle is unique among aluminum alloy discs. It exhibits multiple advantages compared to other aluminum alloys. Its excellent molding properties allow for greater flexibility in the manufacturing process. Whether it is stamping, deep drawing or bending, 3105 Aluminum Circle can handle it easily, providing convenience for manufacturing products of various complex shapes. 3105 aluminum alloy has good corrosion resistance after proper treatment. This means it is resistant to a variety of environmental factors, extending the product’s lifespan. This feature is especially important for outdoor applications or products that require long-term use, ensuring that the product can still maintain good condition in harsh environments. 3105 Aluminum Circle is also known for its excellent welding properties. This enables it to adopt a variety of welding methods, such as gas shielded welding, arc welding, etc., to better meet the needs of different product manufacturing processes. At the same time, its surface treatment process is simple and can achieve a variety of surface effects, such as antioxidant, anti-corrosion, decoration, etc., giving products more choices. In addition, the lightweight and high-strength properties of 3105 aluminum alloy are also unique. Although it has a small specific gravity, it has sufficient strength, making it an ideal choice for manufacturing products with lightweight and high-strength requirements. Its excellent mechanical properties combined with lightweight properties provide greater space for product design and use.

Read More

Industry Knowledge Expansion About This Category

2. What are the applications of aluminum plates in the aerospace and automobile industries?