Search by posts

Calendar

Categories

Popular posts

News

By Admin

By Admin

What effect does the coil temperature have on the coiling of aluminum coils?

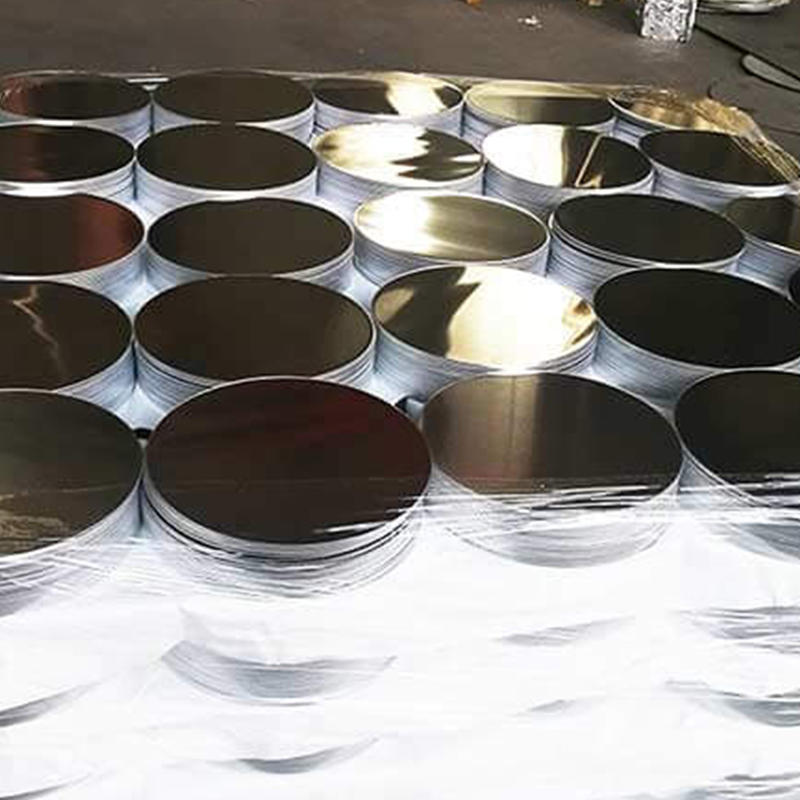

The rolling of aluminum coils refers to rolling flat aluminum materials through a rolling machine or curling equipment to form a rolled product. The rolling temperature plays a vital role in the rolling process of aluminum coils. For aluminum The curling effect, surface quality, internal structure and material properties of the roll have a significant impact.

The coil temperature directly affects the plastic deformation behavior of aluminum coils. At an appropriate rolling temperature, aluminum coils have better plasticity and can be bent and curled more easily, which is conducive to achieving the required curl radius and curl shape. Too high or too low rolling temperature may cause the plasticity of the aluminum coil to weaken, affecting the quality and effect of the curling.

Coil temperature has a significant impact on the surface quality of aluminum coils. Appropriate rolling temperature helps reduce surface defects during the curling process, such as wrinkles, cracks, etc. Too high a rolling temperature may cause surface burns or oxidation of the aluminum coil, while too low a temperature may cause surface wrinkling or uneven curling.

The coil temperature is also closely related to the internal structure and grain structure of the aluminum coil. Appropriate rolling temperature helps maintain the uniform grain structure of aluminum coils and improves its comprehensive mechanical properties. High temperature conditions may promote grain growth and grain boundary recrystallization, while low temperatures may result in insufficient plastic deformation during curling.

In addition, the coil temperature also affects the surface coating, covering layer and other additional treatments of the aluminum coil. At a suitable temperature, the coating can better adhere to the surface of the aluminum coil, improving corrosion resistance and weather resistance. However, if the roll temperature is too high, it may cause burns or oxidation of the coating, affecting its adhesion and protective properties.