Search by posts

Calendar

Categories

Popular posts

News

By Admin

By Admin

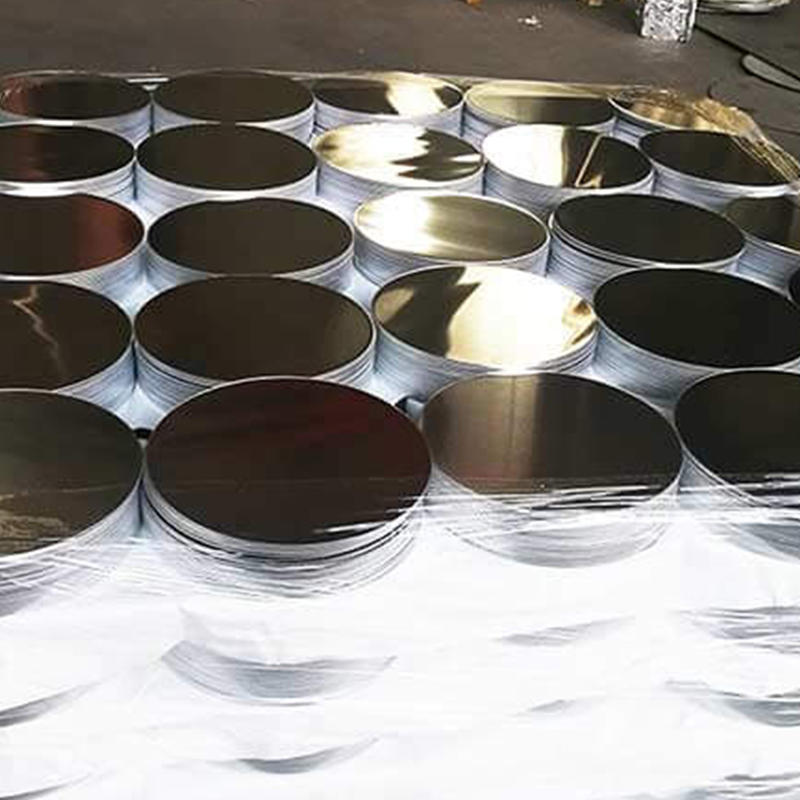

What are the differences between Aluminum Circle 1000, 3000, 4000 and 8000 series?

Aluminum Circles show diverse characteristics and application ranges in different series. From 1000 series to 8000 series, each series has unique chemical composition and physical properties, making it play an important role in their respective fields.

The 1000 series aluminum disc is a pure aluminum product, which is mainly composed of aluminum and a small amount of other elements, such as iron, silicon and copper. This pure aluminum material is often used to make daily necessities such as kitchen utensils and lamps. Its high purity and good processing properties make it ideal for a variety of applications.

3000 series aluminum discs contain aluminum and manganese. This combination gives the aluminum discs excellent corrosion resistance and strength, making them widely used in manufacturing pressure vessels, automotive parts and other fields. At the same time, 3000 series aluminum discs also have good plasticity and processability, making them one of the important materials in many industrial and manufacturing fields.

The 4000 series aluminum wafers contain aluminum and silicon. This kind of aluminum disc has excellent wear resistance and strength and is suitable for manufacturing automotive parts, ship structures and other occasions that need to withstand high stress and friction. Its excellent mechanical properties and durability make it popular in the engineering field.

8000 series aluminum discs contain aluminum, zinc and manganese. This combination gives the aluminum discs excellent strength and corrosion resistance, making them widely used in aerospace, railway vehicles and other fields. In these applications, aluminum wafers not only have to withstand high temperature and high pressure environments, but also need to have excellent durability and stability.