Search by posts

Calendar

Categories

Popular posts

News

By Admin

By Admin

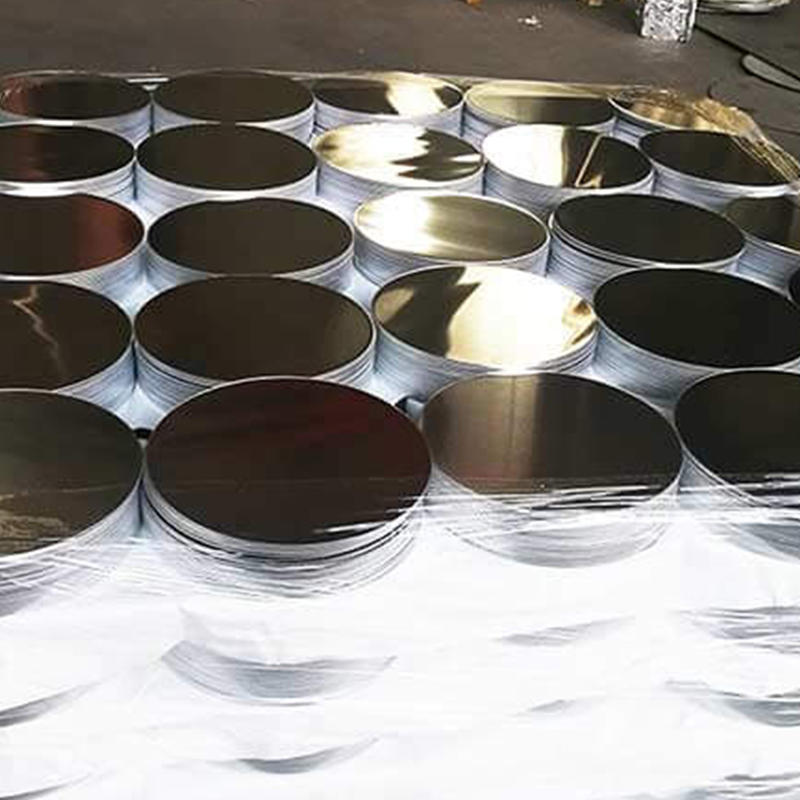

How aluminum discs is made?

Aluminum discs have many uses in our lives and are widely used. They are widely used in electronics, daily chemicals, electrical appliances, machinery manufacturing, automobiles, and other industries. So how are aluminum discs made?

Aluminum rounds are generally cut directly from aluminum coils or aluminum sheets, and then reprocessed. Its processing process is mainly divided into two steps: first, cutting the blank, and then blanking. Let’s talk about the drop in detail.

If the material is coil material, you need to add an uncoil in front.

The automatic aluminum wafer blanking production line is processed as follows:

The aluminum disc uncoiling and blanking production line is a fully automatic and integrated production equipment for aluminum discs. Wide range of applications in the aluminum manufacturing industry, such as: stretched aluminum discs used by cookware manufacturers, stretched aluminum discs used by lighting manufacturers, and aluminum discs, aluminum cans and can seals used in traffic signs All kinds of aluminum discs and aluminum discs required by the first-class series can use integrated production equipment, which can now meet the production needs of a large number of companies for wafer blanks. At the same time, the company’s production efficiency and material application rate have been greatly improved, and the delivery cycle has been shortened.